Flash dryers are preferred for continuous drying and developed for drying filter cakes and sludge-like products. They have application areas especially in the chemical, food and environmental industries.

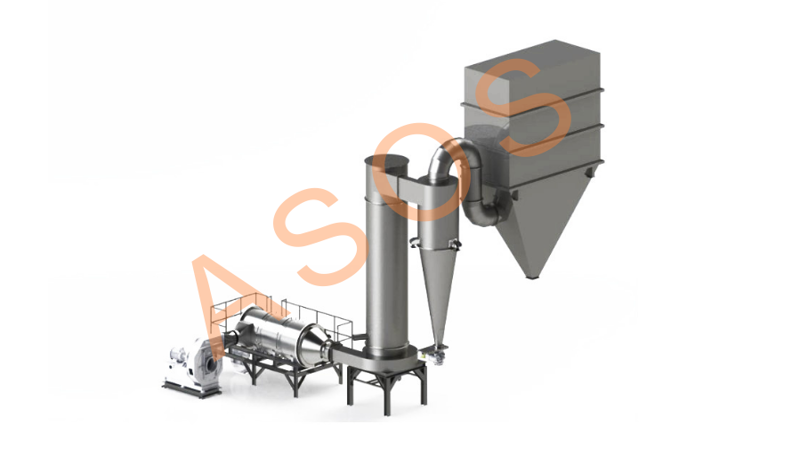

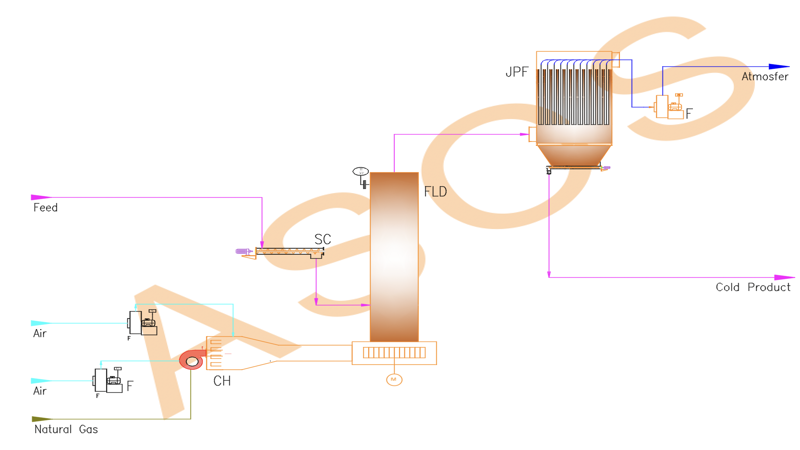

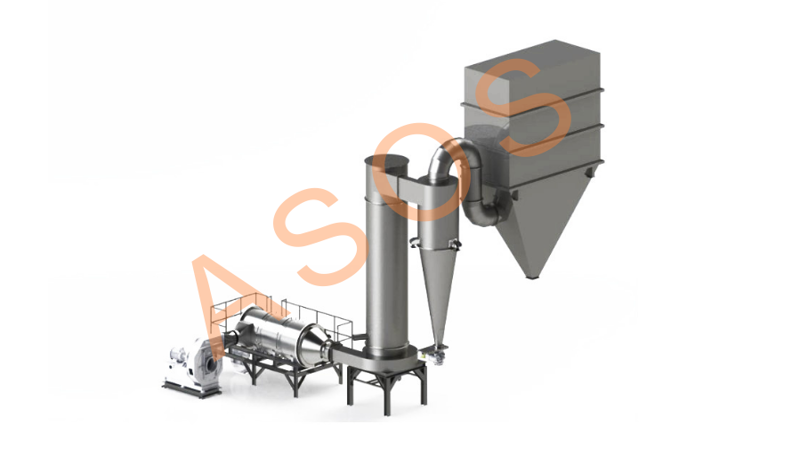

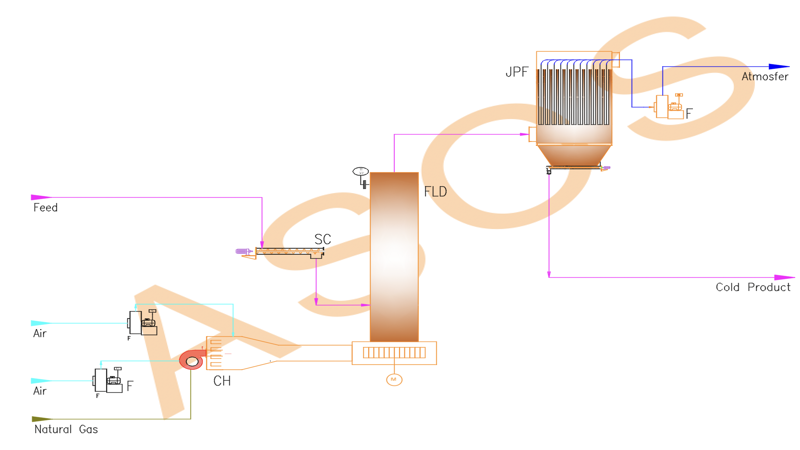

Flash dryer consists of drying body, mixer, feeder, hot air source, air filter, cyclone, bag filter and fans. The moist product enters the drying chamber with a screw feeder. With the effect of the high-speed rotating mixer, the moist product disperses under the influence of impact, friction and shear force and quickly turns into powder. The moist product is completely dried by contacting with hot air. Dry product is taken from the bottom of cyclone and filter.

Advantages:

- Very short contact time with hot air

- High product quality

- Simple design with few moving parts

- Suitable for heat sensitive materials

- Energy saving and system integration

- Low operation and maintenance requirements.