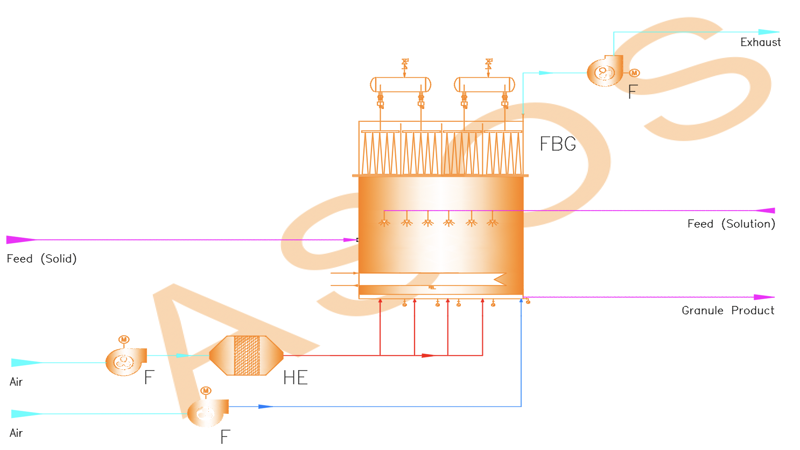

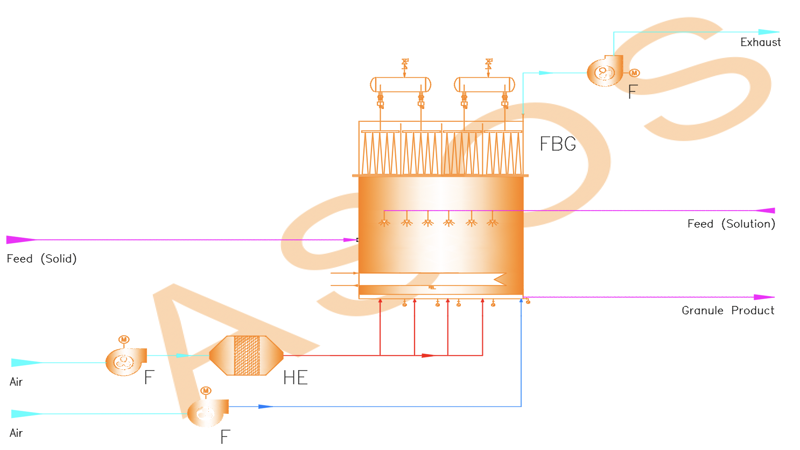

In Fluid Bed Granulation technology, fine particulate materials are fluidized, mixed and dried with hot air. The design of the appropriate air distribution system is important to ensure the mixing of solid particles and heat-mass transfer.

The fluid chosen as the binder is sprayed with an atomizer placed on top, inside or below the fluid bed in the granulator and provides agglomeration.

With the Fluid Bed Granulation technology, porosity, particle size distribution, bulk density and powder content, which are critical properties of the granule product, can be exactly defined.

In Fluid Bed Granulators, spraying distribution, atomizer design and humidity control are of great importance in terms of providing the chemical and physical properties of the desired final granules.

Advantages:

- Short contact time of the product with the binders

- High product quality

- Suitable for heat sensitive products

- Energy-saving

- Ease of maintenance and cleaning.