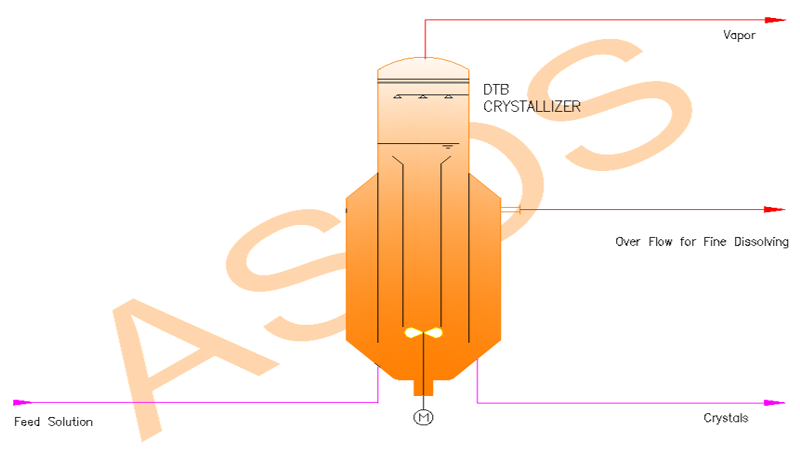

Draft Tube Baffle (DTB) Crystallizers are suitable for processes with vacuum cooling and moderate evaporation rates. Due to the minimal additional heat requirement during the process, they have a positive impact on operating costs.

DTB Crystallizers are typically used in the chemical and fertilizer industries to produce crystalline products such as ammonium sulfate, potassium chloride, monoammonium phosphate, and others.

DTB Crystallizers sometimes operate with low supersaturation, which can be a limitation for crystal growth. Very large crystals can only be produced by dissolving fine particles. In processes where there is no need for or desire to re-dissolve fine crystals, the internal circulation rate of crystallization is adjusted to minimize nucleation effects on the suspension.

To ensure effective control of the crystallization process, it is important to control the residence time and crystal mass to achieve optimum conditions for crystal growth in terms of specific surface area and the fastest possible growth rate. Gravity sedimentation is used to remove the crystal slurry, and the mass flow around the crystallizer is managed to obtain the desired density of the crystal bed.

DTB Crystallizers have an internal or external circulator that pushes the solution upward within a draft tube, and there is a circular settling area outside the crystallizer. The solution inside the crystallizer moves upward at a very low speed. This allows large crystals to return from the draft tube to the main circulation, while only fine crystals smaller than a certain size are re-dissolved along with a change in temperature, thereby creating an additional point of supersaturation.