Cooling of powder and granular products is a common process in many chemical processes. The final products must be cooled before storage or packaging in order to prevent problems such as caking.

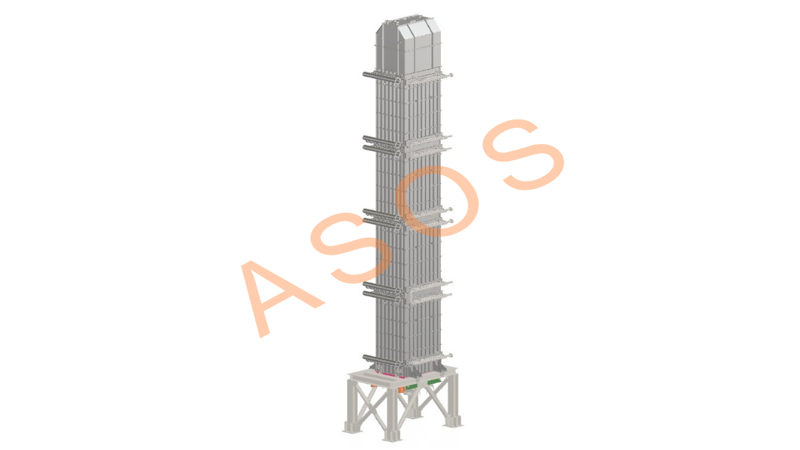

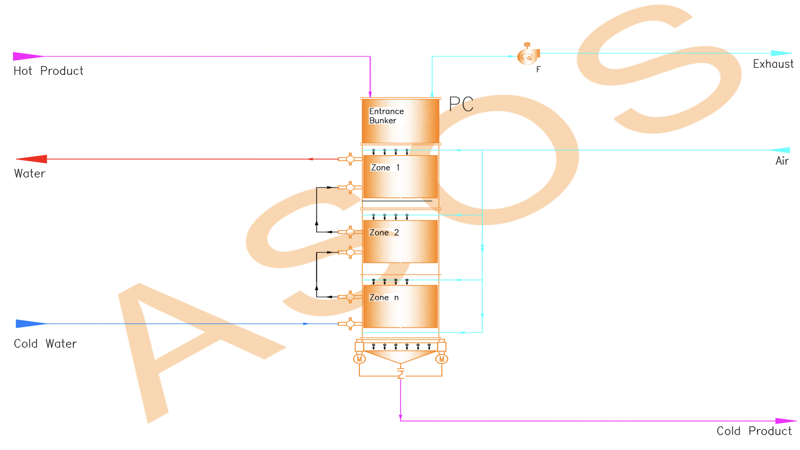

Plate Coolers have a wide range of applications, especially in the chemical and fertilizer industries, instead of rotary drum and fluidized bed coolers, due to their energy efficiency. The basis of the Plate Cooler heat exchanger technology is based on the principle of gravitational movement of the product moving through a set of laser welded plate heat exchangers.

The most common approach to cooling powder and granular products is to keep preconditioned and cooled air in direct contact with the product. This method causes huge energy costs and emission problems.

In Plate Type Cooler technology, the product is cooled indirectly by using cooling water. In indirect cooling technology, chilled water is pumped through a vertically positioned set of hollow stainless steel plates, while the material passes between the plates at a sufficient flow rate to achieve the required cooling. Water is supplied counterflow to the product flow for higher thermal efficiency.

Advantages:

- Up to 80% less energy use

- Zero emissions, dust, hazardous gas and odor

- High product quality

- Constant final product temperature

- Compact and modular design

- Reduced initial investment and setup cost