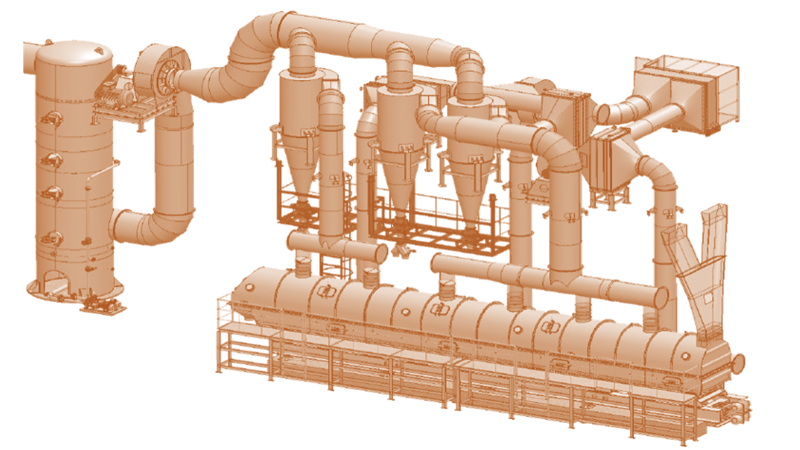

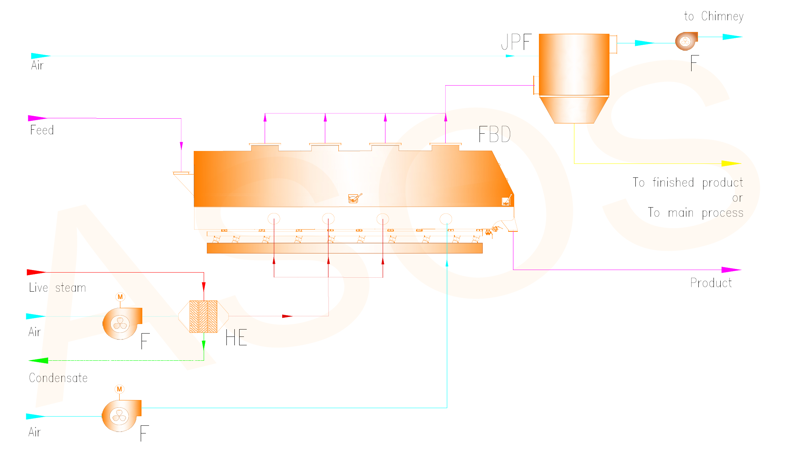

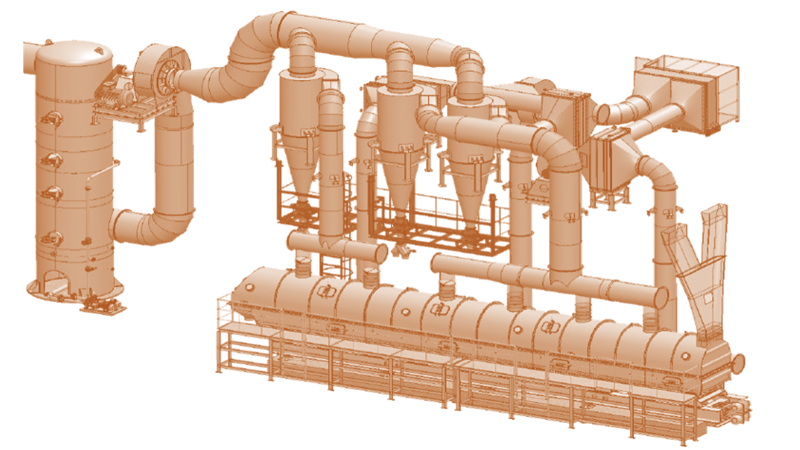

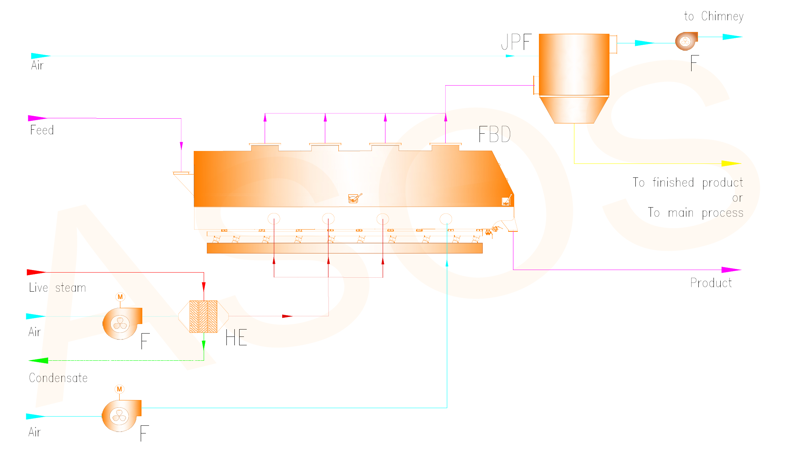

In Fluid Bed Dryers fluidization is created by keeping the particles suspended by passing the pressurized air through the specially designed fan through the solid particles to be fluidized at high speed against the gravitational force acting on the product. A homogeneous structure is formed in the suspended product and thus maximum drying efficiency is provided for the product to be dried.

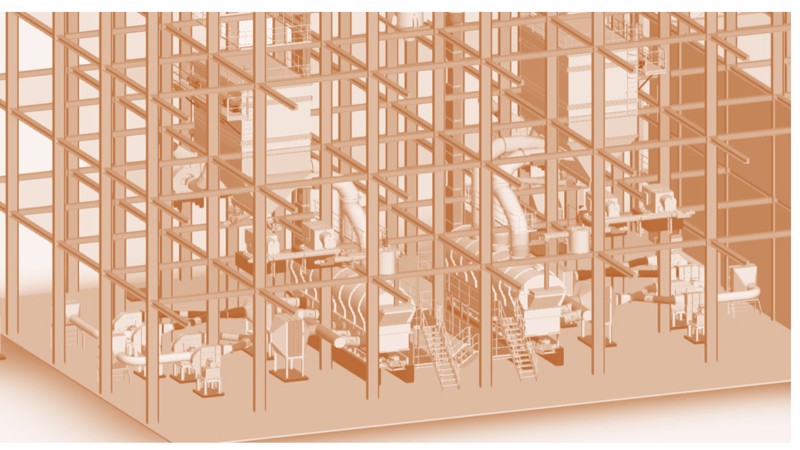

Fluid Bed Dryers & Coolers offer ideal solutions for the chemical, fertilizer and mineral industries. Considering the processes in the industry, drying facilities in particular have high operating and energy costs. Wear and tear caused by the abrasive properties of the dried product means frequent maintenance and repair costs. When all these issues are evaluated, Fluid Bed Dryers provide great advantages in terms of both energy consumption and operation-maintenance.

Fluid Bed Dryers & Coolers are the most suitable solution for granular and crystalline substances.

Advantages:

- Low temperature drying

- Saving energy consumption

- Energy source selection according to different fuel types

- Drying and cooling in the same equipment

- Fast and uniform heat transfer

- Short drying times

- Product drying in sizes between 50 microns and 5 mm